Description

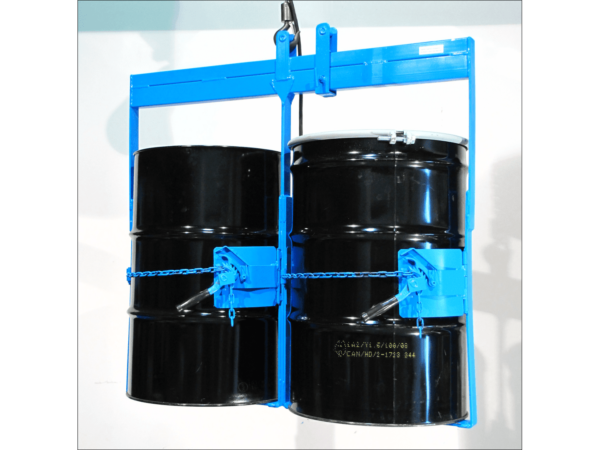

Morse® 86S-2D Use this below-the-hook barrel lifter to transport your drum in an upright position.

The Morse® 86S-2D custom two drum lifter has no tilt function—a below-hook two drum lifter with a positive grip.

We strongly recommend our customers submit an RFQ rather than place an order on the website.

In most cases, we can provide a written quote within hours, including an accurate ship date allowing our customers to consider the delivery date when ordering.

We strive to provide accurate information on the availability of Morse equipment. Some of the factors that affect lead times are:

- Custom equipment and equipment made of select materials built to order

- Standard in-stock designs often require final assembly before shipment

- Delays in components supplied by our vendors

- Current shop backlog when placing the order

In the event of a canceled order, McBrady-McMahon may deduct cancellation charges from any refunds.

Features:

Safety conscious drum lifter hoist attachment for a steel, plastic or fiber drum.

Use this below-the-hook barrel lifter to transport your drum in an upright position. The drum is supported on a bar under the drum and secured with a positive grip chain and ratchet mechanism around the drum.

Attaches to hook on your monorail, crane, or chain block. You may also attach the barrel lift to your forklift using Morse model 284 Fork Mount Hook.

Co., Inc. in Syracuse, NY 13208 USA. Morse Mfg manufactures morse below-the-hook drum handlers and pail handlers. Each is independently load tested at the factory at 125% of rated capacity as per American National Standard ANSI/ASME B30.20 and ships with a Load Test Certificate.

Morse drum lifters comply with ANSI/ASME B30.20 standard for mechanical, below-the-hook lifting devices as it applies to the following:

– Rated load markings and unit identification

– Minimum design safety factor of 3, based on yield strength, for load-bearing structural components

– Welding by certified welders who have passed the ANSI/AWS D14.1 welding qualification test

– All welding is following ANSI/AWS D14.1 and ASME BTH-1