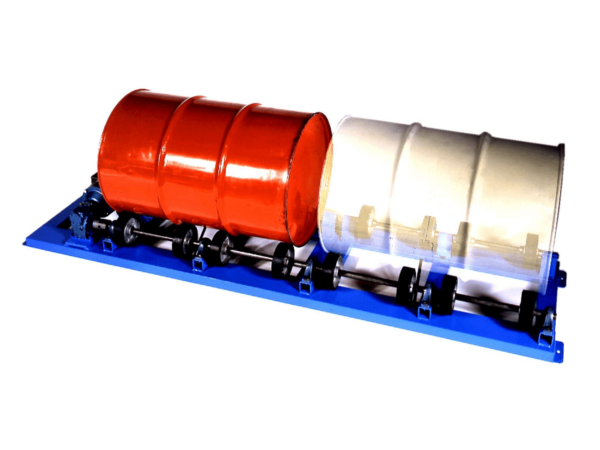

Description

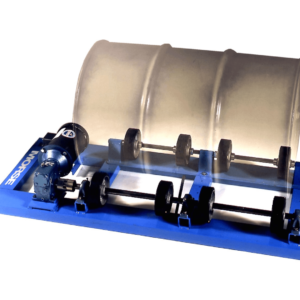

Morse® 2-5154-3 double stationary drum roller, 20 rpm, 1 hp 60hz inverter duty motor. OSHA requires an enclosure. Control Package is sold separately.

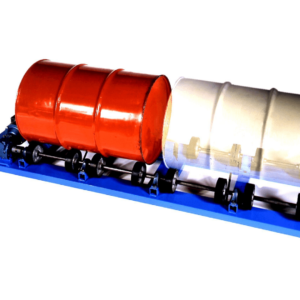

Double Stationary Drum Roller to mix contents of closed drums

Turns drums at 20 RPM

3-phase 60Hz motor

Add Morse Control Package for 1 to 30 RPM

IMPORTANT: OSHA requires an enclosure with an interlock.

Double Drum Roller to gently mix contents inside closed drums

Load horizontal drum onto roller with your crane and a Morse below-hook drum lifter, such as model 41

Roll drums on their side at 20 RPM

RPM is based on 22.5″ (57.15 cm) diameter 55-gallon (210 liter) drum

Add Morse Control Package for 1 to 30 RPM variable speed

Spring steel grounding straps help drain possible static charge from drums

Morse® 2-5154-3 double stationary drum roller is powered by a 1 HP 3-phase 230/460V 60Hz Inverter Duty electric (NON-Explosion Proof) motor

IMPORTANT: OSHA Requires an enclosure with an interlock to automatically turn off the machine if the enclosure is opened.

Enclosure and Interlock Kit are sold separately.

- Roll steel drum with 6″ to 28″ (15 to 71 cm) diameter and maximum 40″ (102 cm) length.

- To roll plastic drums, add Option POLY-2-5154.

- Maximum ambient operating temperature: 140oF (60oC)

- Capacity per Drum:

- 1000 Lb. (454 kg) Liquid load in the drum.

- 300 Lb. (136 kg) Dry load in the drum.

A shifting dry load exerts greater stress on the drum rotator than the fluid motion of a liquid load.