Description

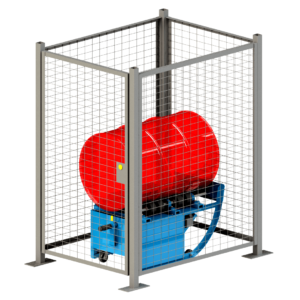

Morse® 201VS-E575 portable drum roller variable speed 15-24 rpm explosion-proof 3-phase 575v motor, motor controls not included (OSHA requires enclosure)

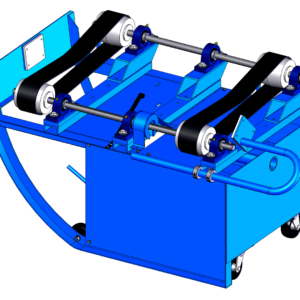

Portable Variable Speed Drum Roller

Vary Drum Rolling Speed from 15 to 24 RPM

Explosion-proof 3-phase 575V 60Hz electric motor

IMPORTANT: OSHA requires enclosure with a safety interlock

We strongly recommend our customers submit an RFQ rather than place an order on the website.

In most cases, we can provide a written quote within hours, including an accurate ship date allowing our customers to consider the delivery date when ordering.

We strive to provide accurate information on the availability of Morse equipment. Some of the factors that affect lead times are:

- Custom equipment and equipment made of select materials built to order

- Standard in-stock designs often require final assembly before shipment

- Delays in components supplied by our vendors

- Current shop backlog when placing the order

For a canceled order, McBrady-McMahon may deduct cancellation charges from any refunds.

Features:

Variable Speed Drum Mixer: Roll a 55-gallon (210 liters) drum at 15 to 24 RPM to mix drum contents

RPM is based on a 22.5″ (57.15 cm) diameter drum

Morse® 201VS-E575 portable drum roller is powered by a 1/2 HP Explosion-Proof 3-phase 575V 60Hz electric motor.

Explosion Proof motors are rated for Class I Group D, and Class II Groups F and G

Ships without a switch, cord and plug. Electrician to install according to local codes and customer’s preference.

IMPORTANT: OSHA Requires an enclosure with an interlock to automatically turn off the machine if the enclosure is opened.

Enclosure and Interlock Kit is sold separately.

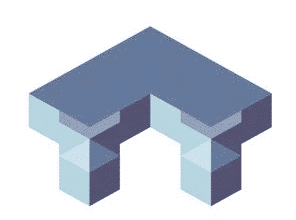

- Roll steel drum with 6″ to 28″ (15 to 71 cm) diameter and up to 38″ (96.5 cm) tall.

- The tipping lever will ONLY engage a drum 30″ (76.2 cm) or taller

- To roll a plastic drum, add Option POLY-201

- Maximum ambient operating temperature: 140oF (60oC)

- Capacity:

- 500 Lb. (227 kg) with Liquid Load in drum

- 300 Lb. (136 kg) with Dry Load in drum

A shifting dry load exerts greater stress on the drum rotator than the fluid motion of a liquid load.