Description

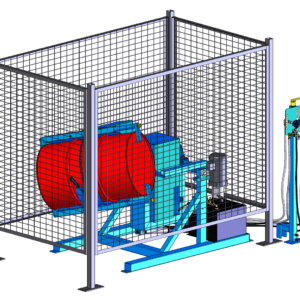

Morse® 310-3 tilt-to-load drum tumbler for plastic, steel or fiber drum 5-20rpm. 3-phase 230/460v 60hz. Osha requires an enclosure. Controls are sold separately.

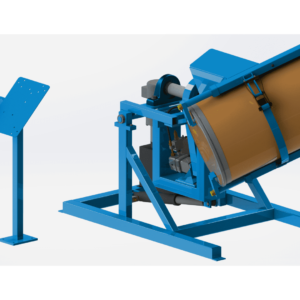

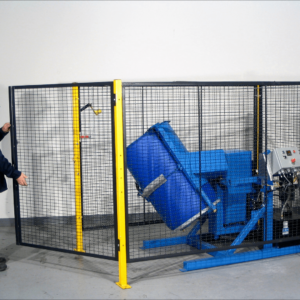

Tilt-To-Load Drum Tumbler turns drum “corner-over-corner” in one direction

LOAD UPRIGHT DRUM AT FLOOR LEVEL

3-phase 60Hz motor

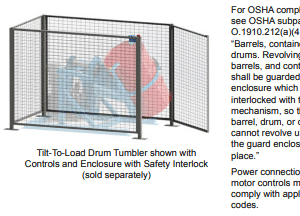

IMPORTANT: OSHA requires enclosure & safety interlock

We strongly recommend our customers submit an RFQ rather than place an order on the website.

In most cases, we can provide a written quote within hours including an accurate ship date allowing our customers to consider the delivery date when ordering.

We strive to provide accurate information on the availability of Morse equipment. Some of the factors that affect lead times are:

- Custom equipment and equipment made of select materials built to order

- Standard in-stock designs often require final assembly before shipment

- Delays in components supplied by our vendors

- Current shop backlog when placing the order

In the event of a canceled order, McBrady-McMahon may deduct cancellation charges from any refunds.

Features:

Morse Tilt-To-Load Drum Tumblers rotate a drum “corner-over-corner” to mix contents vigorously.

Save time, labor and money!

- Morse® 310-3tilt-to-load drum tumbler

- Incorporate valuable ingredients

- Remix stratified layers or sediment

- Eliminate worker exposure exposure

- Reduce cleanup and risk of contamination

Ergonomic Drum Mixing

- LOAD AN UPRIGHT DRUM AT FLOOR LEVEL with a drum hand truck or with your crane and a Morse below-hook drum lifter

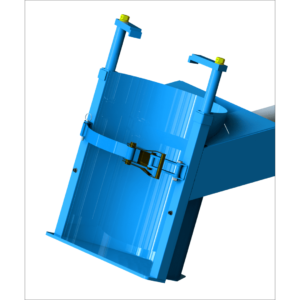

- Secure drum in holder with two top clamps and web strap around the drum

- Turn motor on to activate barrel tumbler hydraulics

- Power Tilt drum with RAISE control valve

- Begin drum rotation with ROTATE control valve

Model 310-3 powered by a 2 HP 3-phase 208/230/460V 60Hz electric (NON-Explosion Proof) TEFC motor.

Morse AC Control Package sold separately.

IMPORTANT: OSHA Requires an enclosure with an interlock to automatically turn off the machine if an enclosure is opened.

Enclosure and Interlock Kit is sold separately.

- Tumble a plastic, steel or fiber drum at 5 to 20 RPM

- Mix products inside a closed drum

- 29″ to 37″ (74 to 94 cm) tall

- 18″ to 23.5″ (46 to 60 cm) in diameter

- Typical 30 to 55 gallon (114 to 210 liter) size drum

- Capacity:

- 800 Lb. (363 kg) Full drum

- 400 Lb. (181 kg) Half-full drum

Half-full capacity is an indication of the capacity for tilting an unbalanced, bottom-heavy drum. A partially full drum with an unbalanced and shifting load is harder to tilt than a full drum.