160 Series 4 Wheel Drum Trucks / Barrel Handling Trucks

Ergonomic Drum Trucks to move and dispense a heavy drum with ease.

4 Wheel Drum Trucks / Barrel Handling Trucks

Ergonomic Drum Trucks to move and dispense a heavy drum with ease.

Morse 4 wheel drum hand trucks

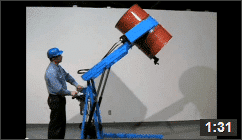

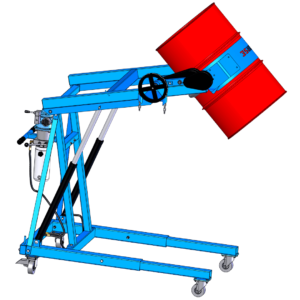

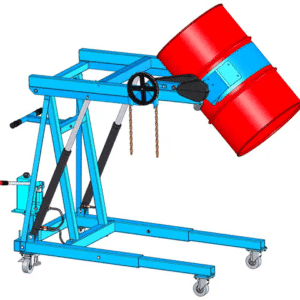

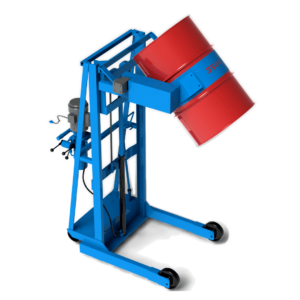

For good reason, model 160 4-Wheel Industrial Drum Truck is our best selling drum truck. The innovative design provides extra safety, ease of use, and versatility.

With this ergonomic drum truck you can load and unload a heavy drum with ease and move a drum quickly and easily in narrow aisles while keeping your hands protected inside the U-shaped Knuckle Saving Handle. Even pour a drum into a 5-gallon (20 liter) pail. The four wheels fully support the drum’s weight, so maneuvering is easy, it turns on a dime. . . and you don’t have to support or balance the load.

Stainless Steel Drum Trucks

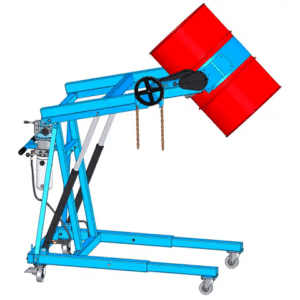

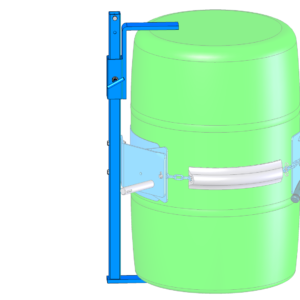

Model 160-SS with polyolefin wheels mounted inside the frame.

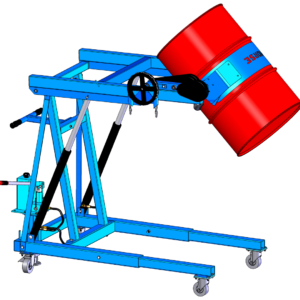

Model 160-WP-SS for rough terrain has rubber tires mounted outside the frame.

Made of finished type 304 stainless steel, these drum trucks are corrosion resistant, and have no paint to wear or chip off.

The innovative design of this stainless steel barrel hand truck provides extra safety, ease of use, and versatility.

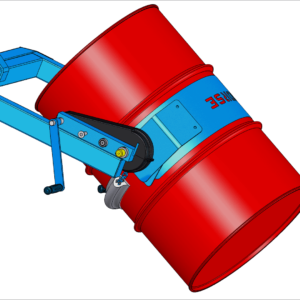

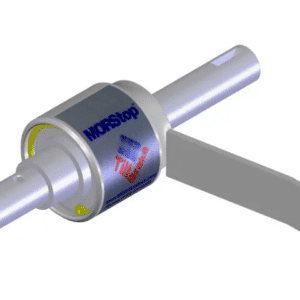

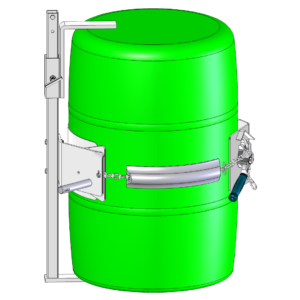

Optional Clamp-On Strap assists in breaking your drum over onto stainless steel drum truck

Strap assists in breaking your drum over onto the stainless steel barrel truck

Stainless steel barrel truck shown with Optional Clamp-On Strap for rimless plastic drum

Related products information

Related Morse Product Details

Related Morse Product Details

-

Morse®160 4-wheel drum truck

$523.60 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 160-SS 4-wheel drum truck, type 304 stainless 1000lb. capacity, polyolefin wheels, move palletize pour 30 55 or 85 gal

$1,292.21 + Shipping and Illinois state sales tax. Add to cart -

Morse® 160-WP-SS drum truck

$1,300.87 + Shipping and Illinois state sales tax. Add to cart