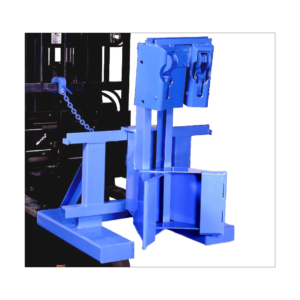

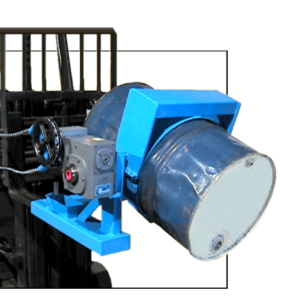

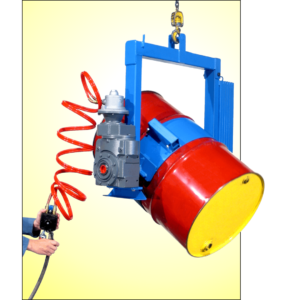

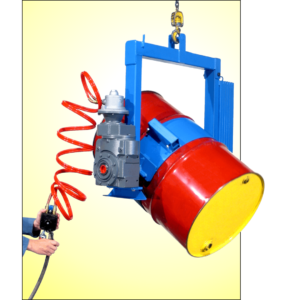

195 Series Powered Drum Handler

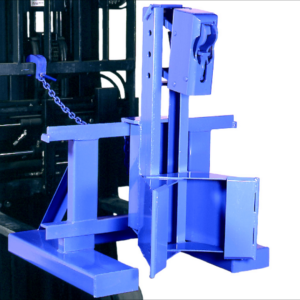

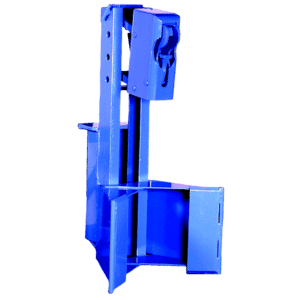

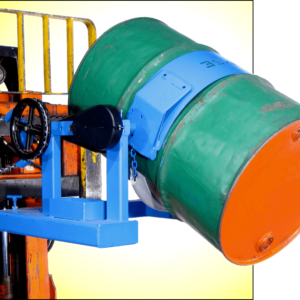

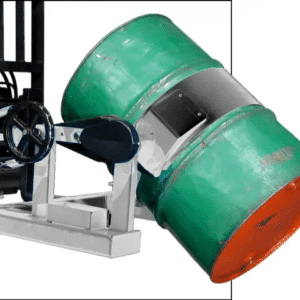

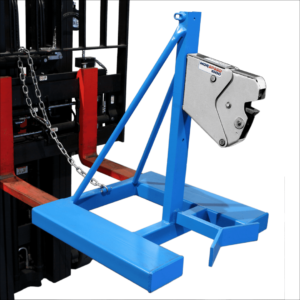

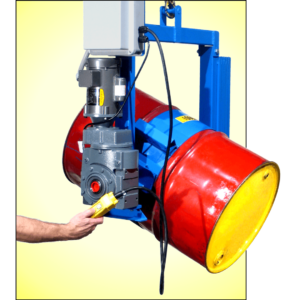

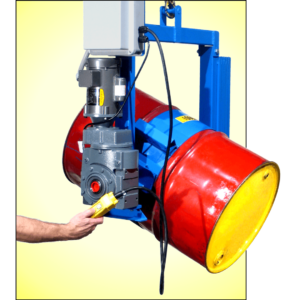

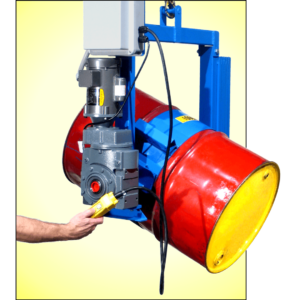

Kontrol-Karriers with Power Drum Tilt Control

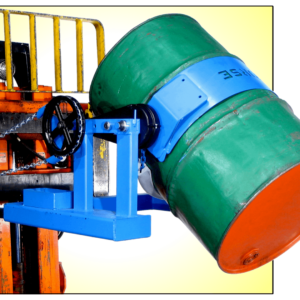

Lift, rotate and pour a heavy drum with your hoist or crane

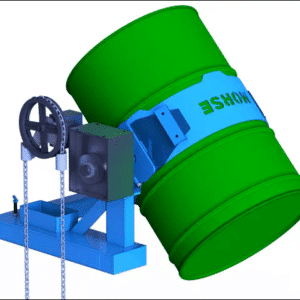

Morse engineers have designed these below-hook lifting devices with motor driven drum tilt for below hook applications. More than just a 55-gallon drum dumper (210 liter drum dumper), you have full 360 degree control of the powered drum rotation to dispense with this industrial lifting equipment.

IMPORTANT: Every Morse below-hook drum handler is individually load tested at the factory at 125% of rated capacity as per American National Standard ANSI/ASME B30.20 and ships with a Load Test Certificate enclosed.

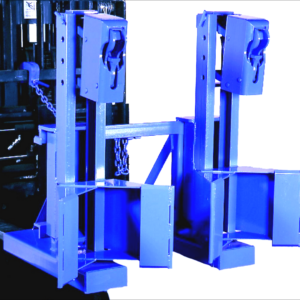

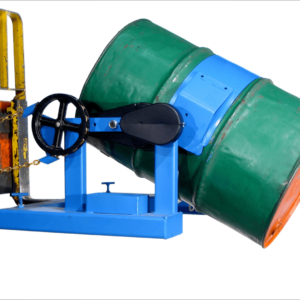

Power Tilt Kontrol-Karriers

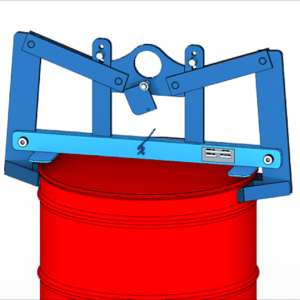

Model 195A-1-115 shown has Power Tilt Kontrol-Karrier with AC power tilt control has a two-button control pendant.

- Motorized drum rotation 360o in both directions

- AC Power Tilt models have 2-button pendant on 7 foot cord (2.1 m cord)

- Air Power Tilt models have 3 position control valve on 6 foot (183 cm) hose

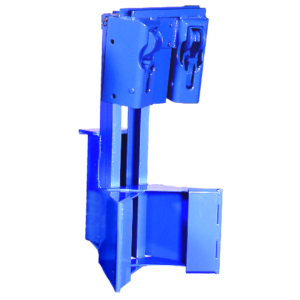

- Available with single phase AC motor, 3-phase AC motor, or air motor

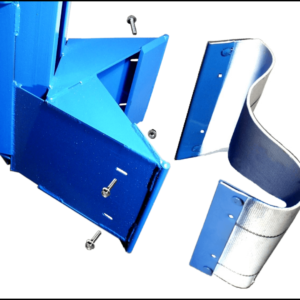

- Designed for 22.5″ (57 cm) diameter 55-gallon steel drum (210 liter steel drum). See options below for other drum types and sizes.

- Capacity: 1500 Lb. (680 kg) Full drum, 800 Lb. (363 kg) Half-full drum

- Order the correct size Diameter Adaptor for each smaller drum

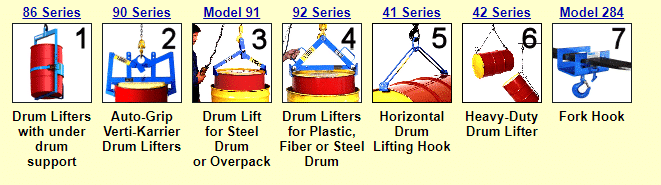

Morse drum lifters comply with ANSI/ASME B30.20 standard for mechanical, below-the-hook lifting devices as it applies to the following:

- Rated load markings and unit identification

- Minimum design safety factor of 3, based on yield strength, for load bearing structural components

- Welding is performed by certified welders who have passed the ANSI/AWS D14.1 welding qualification test

- All welding is in accordance with ANSI/AWS D14.1 and ASME BTH-1

Related products information

Related Morse Product Details

-

Morse 195GM-A kontrol-karrier with spark resistant parts, air power tilt, 3-pc holder for 22.5″ diameter only. 1500 lb. capacity

$99,999.99 + Shipping and Illinois state sales tax. Read more -

Morse Model 195A-1-115 kontrol-karrier with 1-ph 115v 60hz ac power drum tilt, for 22.5″ diameter steel drum. 1500 lb. capacity.

$6,921.20 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195A-3-230 kontrol-karrier with 3-ph 230v 60hz ac power drum tilt, for 22.5″ diameter drum, 1500 lb. capacity.

$6,564.80 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195A-3-460 kontrol-karrier with 3-ph 460v 60hz ac power drum tilt, for 22.5″ diameter drum, 1500 lb. capacity.

$7,075.20 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195A-A kontrol-karrier with air power drum tilt, for 22.5″ diameter drum, 1500 lb. capacity.

$6,745.20 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195G-1-115 kontrol-karrier with 1-ph 115v 60hz ac drum tilt, 3-piece holder for 22.5″ diameter drum only,1500lb. capacity.

$7,448.76 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195G-3-230 kontrol-karrier with 3-ph 230v 60hz ac drum tilt, 3-piece holder for 22.5″ diameter drum only,1500lb. capacity.

$7,143.14 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195G-3-460 kontrol-karrier with 3-ph 460v 60hz ac drum tilt, 3-piece holder for 22.5″ diameter drum only,1500lb. capacity.

$7,647.75 + Shipping and Illinois state sales tax. Add to cart -

Morse Model 195G-A kontrol-karrier with air power drum tilt, 3-piece holder for 22.5″ diameter drum only,1500lb. capacity.

$7,393.32 + Shipping and Illinois state sales tax. Add to cart